- Introduction to shaker screen mesh factories

: Essential industry overview and relevance - Analysis of market demand and global production capacities

- Technological advancements and material innovations

- Comparative analysis of leading shale shaker screen mesh factories

- Customizable solutions and design flexibility

- Application case studies across industries

- Conclusion: Shaker screen mesh factories shaping the future of industrial filtration

(shaker screen mesh factories)

Understanding the Role of Shaker Screen Mesh Factories

Shaker screen mesh factories stand at the core of the solid control and filtration industry, driving efficiency for oil and gas drilling operations, mining, and civil engineering applications globally. These factories specialize in engineering robust, durable shaker screen mesh that ensures optimal separation of solids from drilling fluids. According to a 2023 market research report, the global market size for shale shaker screens exceeded USD 1.2 billion, with a projected compound annual growth rate (CAGR) of 6.8% through 2030. This rapid expansion is fueled by stringent environmental regulations and heightened demand for higher drilling productivity, making high-quality mesh production more critical than ever. By leveraging advanced manufacturing techniques, these factories continuously set new standards in mesh precision, load-bearing capacity, and longevity. Their pivotal role extends far beyond simple production; they serve as innovation drivers and reliable partners for some of the world’s largest energy and engineering companies.

Market Demand and Global Production Capacities

With evolving energy policies and the expansion of unconventional oil extraction, the demand for premium shaker screen mesh and supporting products is surging across continents. In 2022, North America accounted for 38% of total global shaker screen mesh consumption, followed by Asia-Pacific at 29%, reflecting the ongoing surge in shale oil and gas development in these regions. Global shaker screen mesh factories collectively maintain an annual production capacity exceeding 180 million square meters of screening mesh, with 60% of this output classified as high-grade, fine-mesh solutions designed for advanced drilling operations.

Notably, Asian producers have gained traction by investing in high-speed automated weaving and better quality control, closing the gap with traditional Western manufacturers. This emerging geographical shift has given rise to new supply chain dynamics, ensuring that oilfield operators and mining firms can access a broad spectrum of cost-effective and reliable screening solutions. As capacity and capability expand, shaker screen mesh factories are increasingly able to meet stringent delivery timelines for both standard and bespoke mesh specifications.

Innovation and Technological Advancements in Shale Shaker Screen Factories

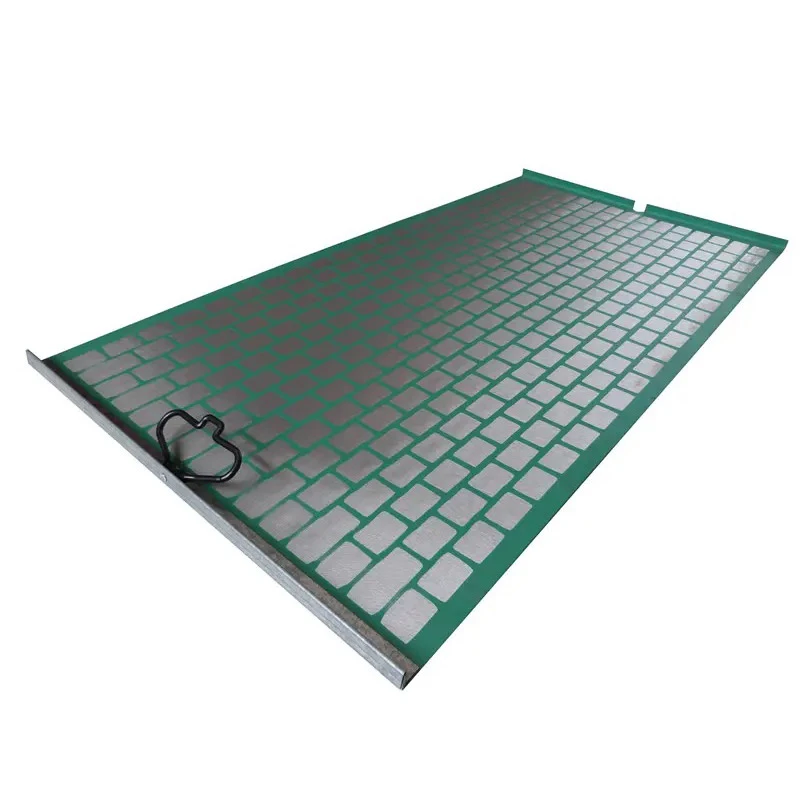

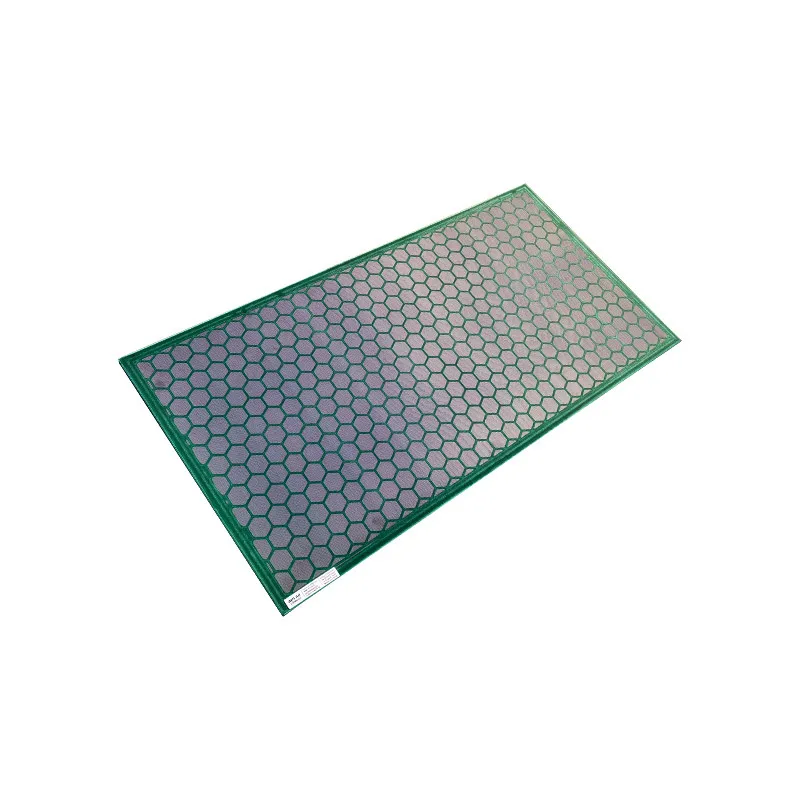

The competitive edge of successful shale shaker screen mesh factories lies in continuous technological innovation. Recent breakthroughs include the integration of nano-coatings, multi-layer composite weaves, and enhanced corrosion resistance. For example, next-generation screens combine stainless steel wire mesh with high-performance polymer layering, extending lifecycle by up to 40% and reducing replacement costs. Automation and digitalization have facilitated inline quality inspection, with AI-powered vision systems capable of detecting mesh defects as minute as 20 microns during production.

Advanced modular engineering allows factories to produce screens compatible with over 90% of global shaker equipment models. Furthermore, proprietary bonding and shaping techniques provide increased open area, improved conductance, and minimized blinding, all essential for higher throughput and finer particle separation. These advances not only boost operational performance but also translate to improved sustainability, lowering waste and reducing the carbon footprint associated with mesh production and disposal.

Comparative Analysis of Leading Shaker Screen Mesh Factories

Choosing the right shaker screen mesh factory is a pivotal decision for operators seeking reliable filtration and separation performance. The following table offers a side-by-side comparison of some of the world’s most prominent factories, evaluated by production volume, range of mesh grades, technological sophistication, global certification, and lead time.

| Factory Name | Annual Capacity (sq.m.) | Mesh Grades Offered | Key Technology | ISO/API Certification | Average Lead Time (days) |

| ScreenPro Solutions | 40,000,000 | API 20–325 | AI-vision QC, Multi-layer Composite | ISO 9001, API Q1 | 12 |

| DongXin Shale Mesh | 30,000,000 | API 60–270 | Nanocoating, Wire-Bond Tech | API Q1 | 15 |

| WaveForm Fab | 22,000,000 | API 20–300 | Automated Laser Cutting | ISO 9001 | 10 |

| Minera Screenworks | 18,000,000 | API 40–230 | Eco-Mesh Polymer Layer | ISO 14001, API Q1 | 13 |

| API Shale Systems | 16,000,000 | API 20–325 | Smart-Shaping Tech | ISO 9001, API Q2 | 14 |

As illustrated, each leading factory has honed unique technological strengths. ScreenPro Solutions, for example, leverages AI-driven quality control, while DongXin Shale Mesh focuses on nanocoating and cutting-edge bonding. These varied approaches enable customers to select suppliers on the basis of both application requirements and regulatory compliance needs.

Customizable Solutions and Design Flexibility

One of the most sought-after attributes in shaker screen mesh factories is the ability to deliver highly tailored screens optimized for specific operational conditions. Through partnerships with original equipment manufacturers (OEMs) and specialized engineering teams, leading factories provide end-to-end design flexibility, including:

- Custom mesh shape and edge bonding for diverse shaker models

- Adjustable mesh aperture sizes to target varying particle cut points

- Selectable base materials (304/316 stainless steel, exotic alloys, composite media)

- Optional anti-corrosion, anti-blinding, and high-capacity reinforcement treatments

- Compatibility testing and certification for international market access

These customizable workflows empower operators to achieve optimal separation efficiency, even when faced with challenging drilling fluids or environmental conditions. In addition, rapid prototyping capabilities have shortened product development cycles, enabling faster site-specific solutions and minimizing downtime.

Application Case Studies Across Key Industries

Shaker screen mesh products engineered by top factories deliver reliable performance in diverse heavy-duty settings. Consider the following application scenarios:

- Deepwater Drilling – Gulf of Mexico: A custom API 200 mesh system supplied by a leading factory resulted in a 27% reduction in solids loading, with screen life extended by 34 days on average, mitigating non-productive rig time.

- Oil Sands Operations – Alberta: Large-format screens with polymer overlays cut replacement frequency in half during critical extraction phases, reducing total cost of ownership by an estimated USD 110,000 annually.

- Municipal Wastewater Treatment – Europe: Ultra-fine hybrid screens enabled the removal of particles down to 20 microns, maintaining regulatory compliance while supporting a sustainable water reuse program.

- Iron Ore Beneficiation – Brazil: Heavy-duty shaker screen installation allowed for continuous 24/7 plant operation, with screen failure rates dropping to less than 0.5% quarterly.

Each case demonstrates a critical intersection of specialized engineering and field-proven durability—key attributes stemming from the expertise housed within modern shaker screen mesh factories. Their ability to respond to real-time challenges ensures sustained operational efficiency, no matter the industry.

The Future Shaped by Shaker Screen Mesh Factories

Shaker screen mesh factories are redefining industrial standards as demands for efficiency, sustainability, and adaptability intensify. With global energy strategies shifting toward higher output and reduced environmental impact, the role of these factories in delivering cutting-edge filtration solutions will continually expand. Data from recent field deployments confirms that customized, high-performance screens enable up to 20% operational cost savings, while simultaneously reducing environmental waste by over 15% compared to legacy systems. As innovation accelerates and global collaboration deepens, shaker screen mesh factories are well-positioned to set the benchmarks for filtration across energy, mining, and environmental sectors.

(shaker screen mesh factories)