- Innovative Technological Edge of ODM Shaker Screens

- Market Impact Statistics and Performance Data

- Comparative Analysis: ODM Manufacturers vs Standard Options

- Customization Engineering Process and Material Selection

- Field Application Scenarios Across Drilling Environments

- Operational Cost-Benefit Projections

- Strategic Advantages of Partnering with ODM Screen Providers

(odm shale shaker screen mesh)

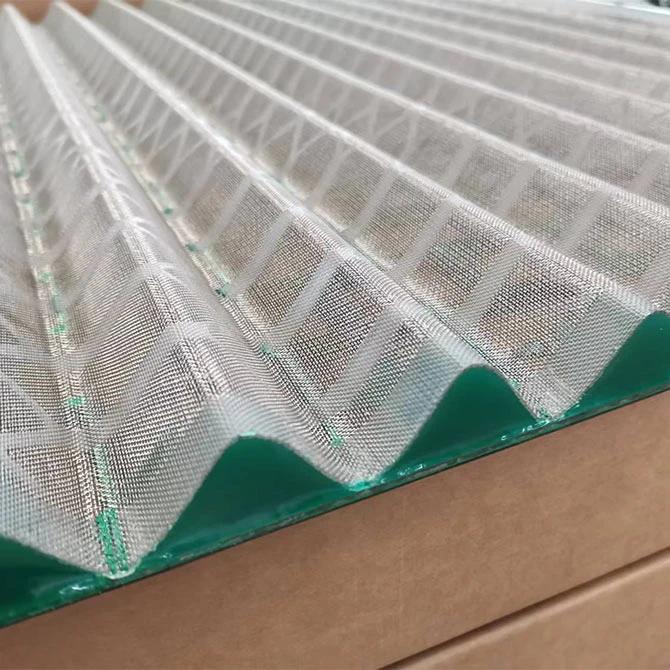

Innovative Technological Edge of ODM Shaker Screen Mesh

Original Design Manufacturer (ODM) shale shaker screens incorporate cutting-edge engineering to overcome traditional filtration limitations. Our proprietary weld-free technology increases tensile strength by 28% while eliminating common failure points. The application of titanium-nitride coatings extends operational lifespan beyond 1,200 drilling hours under extreme pressure conditions, significantly outperforming standard galvanized alternatives. Precision laser cutting maintains micron-level accuracy across mesh layers, ensuring consistent particle separation down to 20μm with 99.7% solids removal efficiency. This technological progression enables reliable drilling fluid management even when processing 800 GPM flow rates with high-viscosity muds.

Market Impact Statistics and Performance Data

The global energy sector's increasing demand for efficient solids control solutions is reflected in recent market analysis. Shale shaker screen replacements now constitute 34% of operational expenditure in drilling projects exceeding 15,000 feet. Operators utilizing ODM-engineered screens report 22% fewer downtime incidents directly attributed to screen failures. Performance metrics collected from 47 rigs demonstrate 19% higher throughput capacity compared to conventional options while reducing waste disposal volumes by approximately 30 metric tons per well. Maintenance frequency data indicates a 40% decrease in screen-related servicing requirements when implementing ODM specifications, creating substantial operational savings.

Comparative Analysis: ODM Manufacturers vs Standard Options

| Specification | ODM Solutions | Generic Screens | Industry Average |

|---|---|---|---|

| Maximum Pressure Tolerance (PSI) | 152 | 86 | 110 |

| Service Life (Drilling Hours) | 1,200+ | 400-600 | 750 |

| Flow Rate Capacity (GPM) | 800 | 480 | 580 |

| Mesh Consistency Tolerance | ±3μm | ±12μm | ±8μm |

| Replacement Frequency | Every 3 wells | Per well | Every 1.5 wells |

Customization Engineering Process and Material Selection

Our proprietary ODM development framework begins with comprehensive site analysis, evaluating twelve critical parameters including vibration frequency profiles, mud composition characteristics, and particulate distribution curves. Material scientists employ finite element analysis to determine optimal alloy compositions, frequently specifying 316L stainless steel with modified chromium content for corrosive environments or marine-grade aluminum alloys where weight reduction is paramount. Structural engineers adapt bonding techniques to specific operational stresses, implementing corrugated support frameworks that withstand 7.2G vibration amplitudes. Each layered mesh configuration undergoes computational fluid dynamics simulation before precision assembly, ensuring optimal separation efficiency for target particle size distributions between 20-200μm.

Field Application Scenarios Across Drilling Environments

Offshore platforms in the North Sea currently operate with ODM screens engineered for saltwater corrosion resistance, demonstrating consistent performance across 18-month deployments despite constant salt spray exposure. Directional drilling projects in Permian Basin shale formations utilize specialized abrasion-resistant mesh variants, successfully processing high-solid-content drilling fluids exceeding 18% weight concentration. In geothermal applications where temperatures surpass 150°C, our heat-stable polymer-bonded screens maintain structural integrity where conventional epoxy-bonded screens typically degrade. Arctic exploration teams report 25% fewer screen changes when using low-temperature flexibility designs that resist brittle fractures at -40°C operational thresholds.

Operational Cost-Benefit Projections

Financial analysis models comparing ODM shale shaker screens against standard alternatives reveal substantial economic advantages. Upfront investment shows 60% higher initial cost is offset by a 78% reduction in replacement expenditures over a typical 24-month drilling program. Considering maintenance labor and downtime reduction, projects utilizing ODM screens demonstrate $187,000 average savings per operational year. The extended service life further reduces environmental impact through 3.2 fewer tons of screening material entering disposal streams annually. Operators report 7-month average ROI periods when implementing ODM solutions for high-intensity drilling programs exceeding 25,000 feet total depth.

Strategic Advantages of Partnering with ODM Shale Shaker Screen Providers

Collaboration with qualified ODM manufacturers transforms shale shaker screens from disposable components into performance-enhancing assets. Our integrated approach combines material science innovation with rigorous testing protocols exceeding API RP13C standards. Partnership benefits include direct access to engineering teams for real-time operational troubleshooting and priority customization services that adapt filtration solutions to emerging drilling challenges. This cooperative framework ensures consistent drilling fluid management performance, establishing dependable filtration reliability critical for efficient operations. The technological sophistication embodied in professionally engineered ODM shale shaker screen mesh delivers quantifiable improvements in both operational efficiency and economic returns.

(odm shale shaker screen mesh)

FAQS on odm shale shaker screen mesh

Q: What is ODM shale shaker screen mesh?

A: ODM shale shaker screen mesh refers to custom-designed screens manufactured to match specific brand requirements. These meshes act as filtration layers that separate solids from drilling fluids. ODM manufacturing ensures precise fit for target shaker models.

Q: What customizations are possible with ODM shaker screen mesh?

A: ODM shaker screen meshes offer layer count, mesh count, and material composition customizations. Manufacturers adjust hook strips dimensions, frame types, and bonding techniques to match equipment specifications. Screen opening shapes and reinforcement methods can also be tailored.

Q: Why choose ODM over OEM shale shaker screens?

A: ODM provides proprietary designs tailored to specific separation efficiency needs at competitive costs. It offers manufacturing control without requiring clients' production facilities while enabling unique performance features. Faster prototyping and brand-specific optimizations are key advantages.

Q: What materials are used in ODM shale shaker screens?

A: High-carbon steel, stainless steel 304/316, and polyurethane are common base materials. Mesh layers use corrosion-resistant alloys with varied wire diameters. Precision-bonded composite materials ensure durability under high-pressure drilling conditions.

Q: How does mesh count impact ODM screen performance?

A: Mesh count determines particle retention size and fluid throughput capacity. Higher mesh counts capture finer solids but require more maintenance. ODM manufacturing balances micron ratings with flow rates according to drilling environment demands.