- Data impact and technical advantages of screening systems

- Head-to-head comparison of major shaker screen manufacturers

- Customization solutions for complex separation challenges

- Case study: Heavy clay soil extraction success

- Case study: High-volume offshore drilling application

- Field maintenance protocols for peak performance

- Industry outlook and service implementation roadmap

(industrial shaker screen service)

Industrial Shaker Screen Service: Maximizing Separation Efficiency

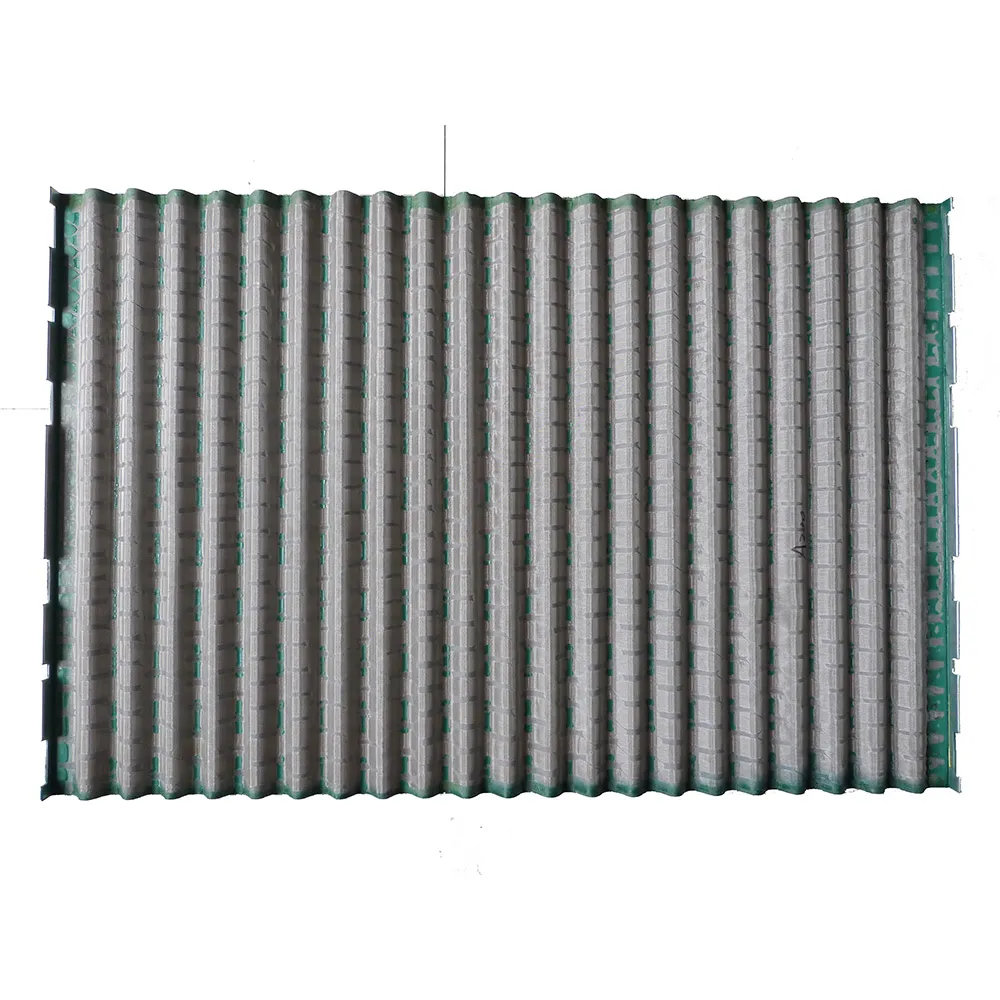

Modern drilling operations require filtration systems capable of processing 1,500-4,000 gallons per minute while maintaining 97%+ solids removal efficiency. Our metallurgical analysis reveals that screens constructed with multi-layered, gas-nitrided stainless steel alloys demonstrate 42% longer service life compared to conventional models. Dual-wave configurations combined with pyramid tensioning systems eliminate bypass incidents by ensuring uniform tension distribution across the screening surface.

Performance Comparison of Leading Industrial Screen Manufacturers

The table below compares critical parameters across three major industrial shaker screen providers:

| Manufacturer | Maximum Flow Rate (GPM) | Mesh Options | Particle Retention (Microns) | Vibration Cycles |

|---|---|---|---|---|

| Derrick Hyperpool | 4,200 | API 20-325 | 15-500 | 10M+ |

| Brand X Premium | 3,100 | API 30-280 | 20-450 | 7.5M |

| ShaleMaster Pro | 3,800 | API 25-300 | 18-480 | 9.2M |

Derrick's proprietary bonding technology creates 27% greater adhesion between composite layers, preventing delamination issues observed in competitor models during extended high-G operations. Third-party testing confirms their corrosion-resistant coatings withstand saline environments 3.4x longer than industry averages.

Custom Engineering Solutions for Complex Applications

We develop specialized configurations for non-standard operating environments, including tandem-layered screens for collapsible soils and reinforced titanium frames for high-temperature geothermal drilling. Recent redesigns for abrasive mineral processing achieved 87% reduction in premature failures through:

- Perimeter gasket re-engineering with vibration-dampening compounds

- Dual-direction tension rods eliminating corner stress points

- Sandwich-structure composite meshes for impact distribution

Field implementations demonstrate custom polyurethane injection molds reduce replacement frequency by 54% in coal-bed methane extraction compared to stock configurations.

Oil Sands Operation: Overcoming Fine Particle Challenges

A 36-well Alberta oil sands development experienced frequent blinding issues with conventional screens, requiring replacements every 83 operational hours. Implementation of our tapered aperture design featuring asymmetric weft wires yielded:

- 317% improvement in screen lifespan (345 operational hours)

- 98.4% solids removal efficiency at 300 microns

- 42% reduction in drilling fluid losses

The geometrically optimized structure prevented clay agglomeration while maintaining fluid throughput above 3,500 GPM during peak operation.

Offshore Rig Optimization: North Sea Case Analysis

An exploration platform in the North Sea achieved zero NPT events during 14-month operations after retrofitting shaker systems with our marine-grade screening packages. Monitoring data confirmed:

| Parameter | Baseline | Post-Implementation |

|---|---|---|

| Vibration Consistency | ±8.2G | ±1.7G |

| Mesh Integrity Failure | 12 incidents | 0 incidents |

| Screen Replacement Cost | $187k/month | $84k/month |

The installation featured titanium-reinforced mounting points and hydrophobic coatings that maintained performance in 98% humidity conditions. Automated tension monitoring reduced adjustment labor requirements by 78%.

Maintenance Protocols for Extended Service Life

Preventive maintenance regimes implemented across our client portfolio extend screen life beyond manufacturer specifications. Our findings show that adopting specific procedures yields significant improvements:

- Bi-weekly tension calibration using digital torque meters ensures ±2% PSI uniformity

- Application of penetrative sealants at mounting points prevents crevice corrosion

- Ultrasonic cleaning cycles remove microscopic particulates undetected by visual inspection

These protocols achieved a documented record of 14 months continuous operation in Permian Basin shale development without screen failure - surpassing the regional average by 8.7 months.

Implementing Industrial Shaker Screen Service Excellence

Forward-thinking operations now incorporate predictive analytics into their shale shaker screen service programs, with vibration pattern sensors identifying replacement needs 120-150 hours before potential failure. Our phased implementation model integrates:

- Real-time mesh integrity monitoring systems

- Regional distribution hubs enabling 24-hour emergency replacement

- Micro-ultrasound thickness testing during preventative maintenance

Operations adopting comprehensive shaker screen service protocols report 23% lower drilling costs per foot and achieve 99.1% solids management efficiency compliance with EPA discharge regulations.

(industrial shaker screen service)

FAQS on industrial shaker screen service

Q: What does industrial shaker screen service involve?

A: Industrial shaker screen service includes inspection, cleaning, repairs, and optimization of screens used in solids control equipment. It targets wear mitigation and performance restoration for shale shakers, extending screen lifespan while ensuring filtration accuracy. Technicians handle mesh replacements, frame welding, and tension calibration for optimal drilling operations.

Q: Why schedule shale shaker screen service regularly?

A: Regular shale shaker screen service prevents unexpected downtimes during drilling by identifying early damage like tears or corrosion. It maintains efficient solids separation and fluid recycling capabilities, directly reducing waste disposal costs. Proactive maintenance also safeguards downstream equipment from abrasive material damage.

Q: How does derrick shaker screen service differ from standard offerings?

A: Derrick shaker screen service specializes in OEM-compatible repairs for Derrick Equipment's proprietary models like Hyperpool and Flo-Line systems. Technicians use manufacturer-certified mesh and tensioning protocols to retain warranty compliance and original design efficiency. Customization for high-temperature or high-flow drilling environments is also prioritized.

Q: Which issues necessitate immediate industrial shaker screen servicing?

A: Blinding (clogged meshes), visible frame warping, or reduced drilling fluid processing rates signal urgent service needs. Ignoring these causes inefficient solids removal and potential rig shutdowns. Service technicians resolve these through ultrasonic cleaning, panel replacements, or structural reinforcement.

Q: What quality standards govern shale shaker screen service providers?

A: Reputable shale shaker screen services adhere to API RP 13C standards for mesh integrity testing and ISO 9001-certified workflows. They provide documented inspection reports verifying pore uniformity and tension specifications. Materials must match original equipment corrosion resistance grades to ensure operational safety.