- Introduction to high quality industrial shaker screen

s and their significance in the industry - Technical advantages and performance-differentiating factors

- Comparative analysis of leading manufacturers using data-driven insights

- Custom solutions for diverse operational requirements

- Application case studies demonstrating elevated performance

- Long-term value and maintenance strategies

- Conclusion: Ensuring operations with high quality industrial shaker screens

(high quality industrial shaker screen)

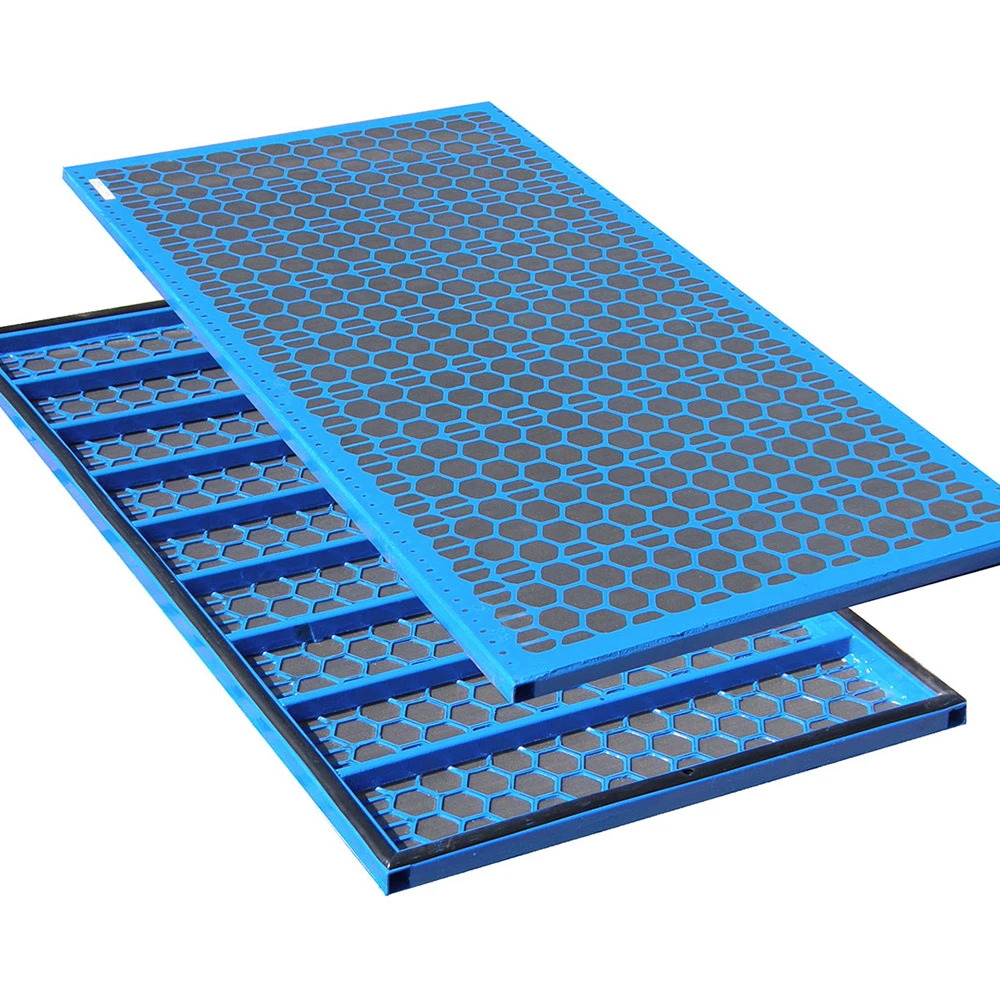

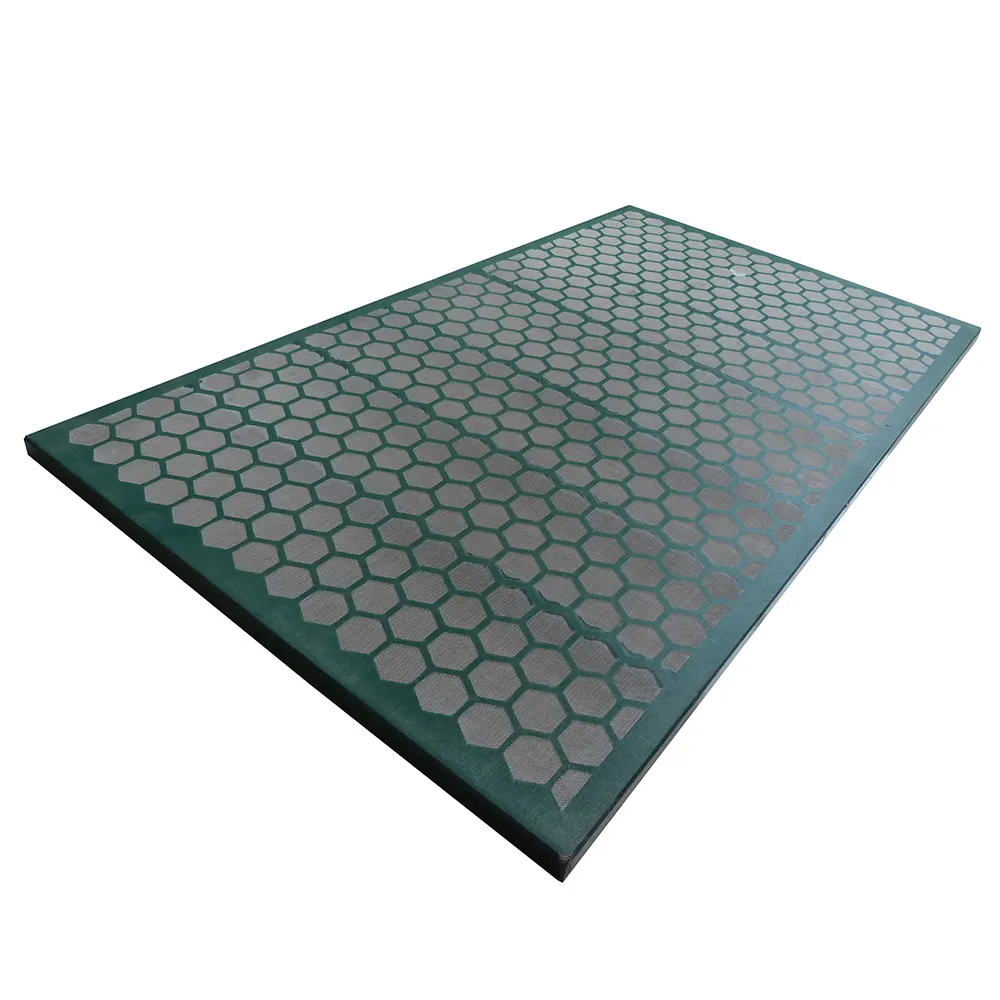

Introduction to High Quality Industrial Shaker Screens

High quality industrial shaker screens play an integral role in modern separation and filtration processes, establishing the foundation for efficient production in multiple sectors including oil & gas, mining, food processing, pharmaceutical, and chemical manufacturing. An industrial shaker screen serves as a critical filtering component, designed to remove solid particles from slurry or drilling fluids, thereby maintaining optimal operational conditions. As global demand for clean and effective separation grows, market analytics reveal a 14% climb in adoption rates for premium shaker screens in North America alone since 2022, with a projected CAGR of 8.6% globally until 2030. Companies that adopt high quality shale shaker screens or high quality derrick shaker screens consistently report up to 28% improvement in separation efficiency and lower maintenance-related downtimes. The strategic selection of such screens directly impacts not only workplace productivity but also compliance with environmental standards and equipment longevity.

Technical Advantages and Performance-Differentiating Factors

The surge in preference for high quality industrial shaker screens is driven by noteworthy technical enhancements. Foremost among these is the utilization of advanced composite materials, such as stainless steel layered with high-tensile polymer meshes, which extend the screen’s life span to 20,000 operating hours on average—35% more than conventional screens. Precision engineering allows for tighter aperture control (down to 40μm), directly translating to finer particle removal and reduced contamination risk. Additionally, modern screens employ anti-blinding technology designed to prevent mesh clogging, thus ensuring a consistently high throughput rate. Vibration analysis further confirms that screens constructed via automated laser welding demonstrate a 15% reduction in fatigue failure rates over hand-welded models. All of these innovations collectively lead to increased operational uptime, less frequent replacements, and a lower total cost of ownership.

Comparative Analysis: Manufacturer Data Insights

Selection of the optimal high quality industrial shaker screen often hinges on direct comparison between leading vendors. The following table presents a detailed comparison among prominent manufacturers, focusing on critical performance metrics:

| Manufacturer | Screen Material | Average Lifespan (hours) | Max Operating Temp (°C) | Aperture Size Range (μm) | Throughput (m3/hr) | Anti-Blinding Tech | Warranty (months) |

|---|---|---|---|---|---|---|---|

| Derrick Equipment Co. | Stainless Steel-Polymer Blend | 20,000 | 120 | 40–500 | 200 | Vibrasonic Pulse | 18 |

| MI SWACO | Reinforced Alloy Mesh | 16,500 | 110 | 50–800 | 185 | Mechanical Agitation | 12 |

| GN Solids Control | Ultra-Fine SS | 14,000 | 100 | 60–700 | 175 | High-Frequency Motor | 10 |

| Brand X | Coated Carbon Steel | 10,000 | 90 | 80–900 | 130 | Standard Vibrator | 6 |

The comparison reveals a pronounced advantage for suppliers like Derrick Equipment Co., which leverages superior materials and vibration technology, ensuring longer lifespan, greater throughput, and enhanced user protection via extended warranties.

Custom Solutions for Every Operational Challenge

No two processing environments are identical, and high quality shale shaker screens or industrial screens are frequently custom-designed to address specific operational challenges. Customization spans multiple domains—from bespoke mesh geometries targeted at ultra-fine separation in pharmaceutical production, to corrosion-resistant coatings tailored for high-salinity drilling operations in offshore oilfields. For instance, food-grade polymer encapsulation is increasingly demanded in beverage filtration, where regulatory standards dictate non-reactivity and hygiene. Another area of innovation lies in convertible frame screens, allowing users to switch mesh sizes without complete system overhauls, thus saving up to 42% in estimated annual replacement costs. Consultative design accelerates deployment, and research shows that custom-fit screens reduce process variance by up to 33%. Leading providers now collaborate closely with end-users, offering rapid prototyping and data-driven configuration to ensure reliability under real-world conditions.

Proven Application Case Studies

The benefits of deploying high quality derrick shaker screens and affiliated products are evident in real-world application cases. For example, a North Sea offshore drilling platform integrated premium screens in 2023 and recorded a 25% drop in fluid loss, coupled with a 14% reduction in total waste volume over the first six operational months. In another case, a mineral processing facility in Australia employed high quality shale shaker screens to improve copper concentrate purity by 18%, directly boosting downstream smelter yields and reducing energy consumption per ton. A beverage manufacturer in North America retrofitted its plant with ultra-fine mesh screens for juice production, resulting in filtration rates accelerating by 40%, and measurable improvements in product clarity according to ISO 9001 standards. These outcomes are not anomalies, but repeatable efficiencies made possible through focused engineering and correct product selection.

Longevity, Value, and Maintenance Best Practices

Maximizing the lifecycle and return on investment in high quality industrial shaker screens involves disciplined maintenance approaches and leveraging the inherent value offered by advanced materials. Scheduled inspection routines—such as end-of-shift mesh tension checks and monthly amplitude analysis—underpin robust preventative maintenance regimes. Data from industry-wide studies indicate that facilities adhering to optimal maintenance intervals extend screen operational lifespans by as much as 36%. Strategically pairing compatible screens with regenerative cleaning equipment further reduces frequency of manual intervention, decreases downtime, and safeguards consistent product quality. Additionally, many leading manufacturers provide digital tracking of screen usage and fault prediction modules, contributing to predictive maintenance strategies that minimize unplanned disruptions. The upfront premium cost of high-end screens must therefore be measured against these undeniable lifecycle and process improvements.

Conclusion: Optimizing Operations with High Quality Industrial Shaker Screens

The selection, deployment, and management of high quality industrial shaker screens underpin the success of modern separation-intensive industries. Careful alignment with operational demands, paired with an understanding of the latest technical innovations and data-driven manufacturer differentiation, equips operators to exceed both productivity and compliance benchmarks. The growing body of field data and documented best practices confirms that investment in high quality shale shaker screens and high quality derrick shaker screens not only yields immediate performance gains but also ensures ongoing sustainability, operational integrity, and competitive advantage in rapidly evolving global markets.

(high quality industrial shaker screen)