- Introduction to derrick shaker screen quotes

and relevance in the oil & gas industry - Technical advantages of high-quality shaker screens and the importance of mesh parameters

- Critical cost and performance comparison among leading manufacturers

- Customized shaker screen solutions for diverse operational demands

- Real-world applications and impactful success stories

- Guidelines for selecting the optimal shaker screen for your operation

- Conclusion: The value and benefits of sourcing accurate derrick shaker screen quotes

(derrick shaker screen quotes)

Unlocking Value with derrick shaker screen quotes: Industry Insights

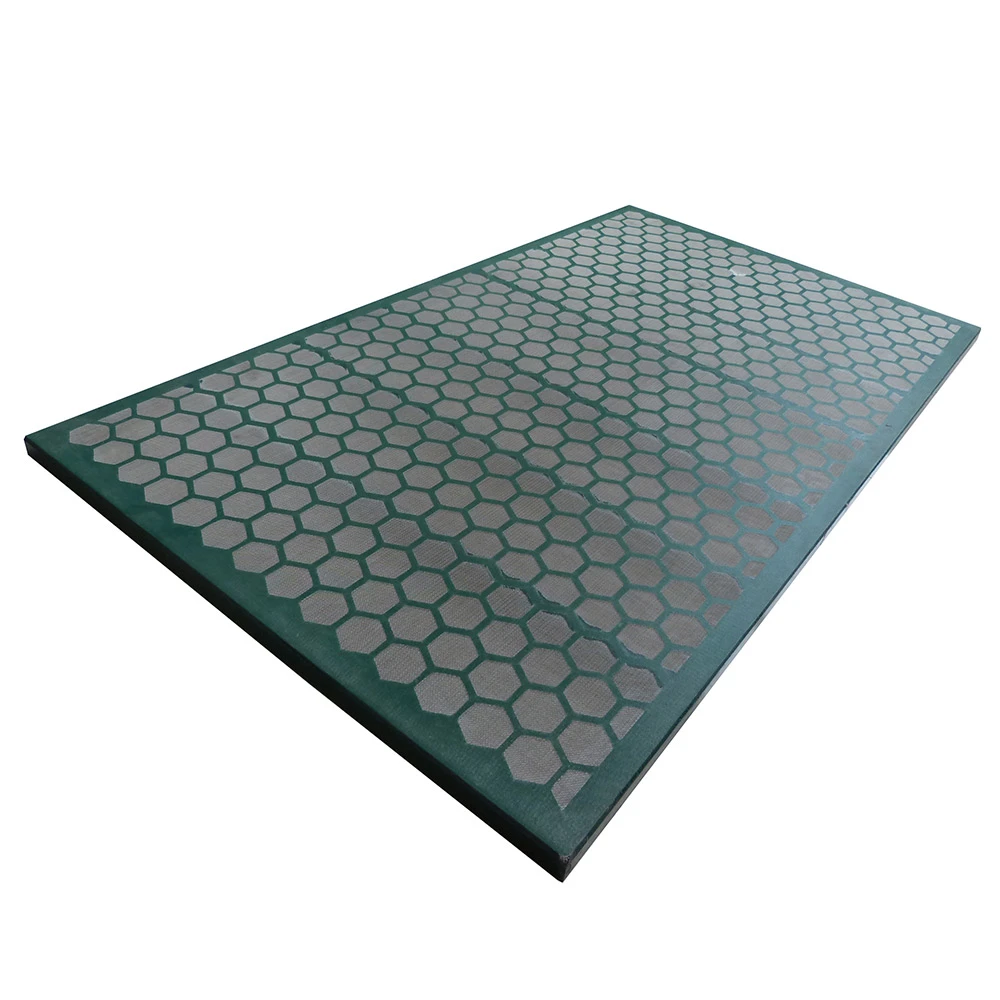

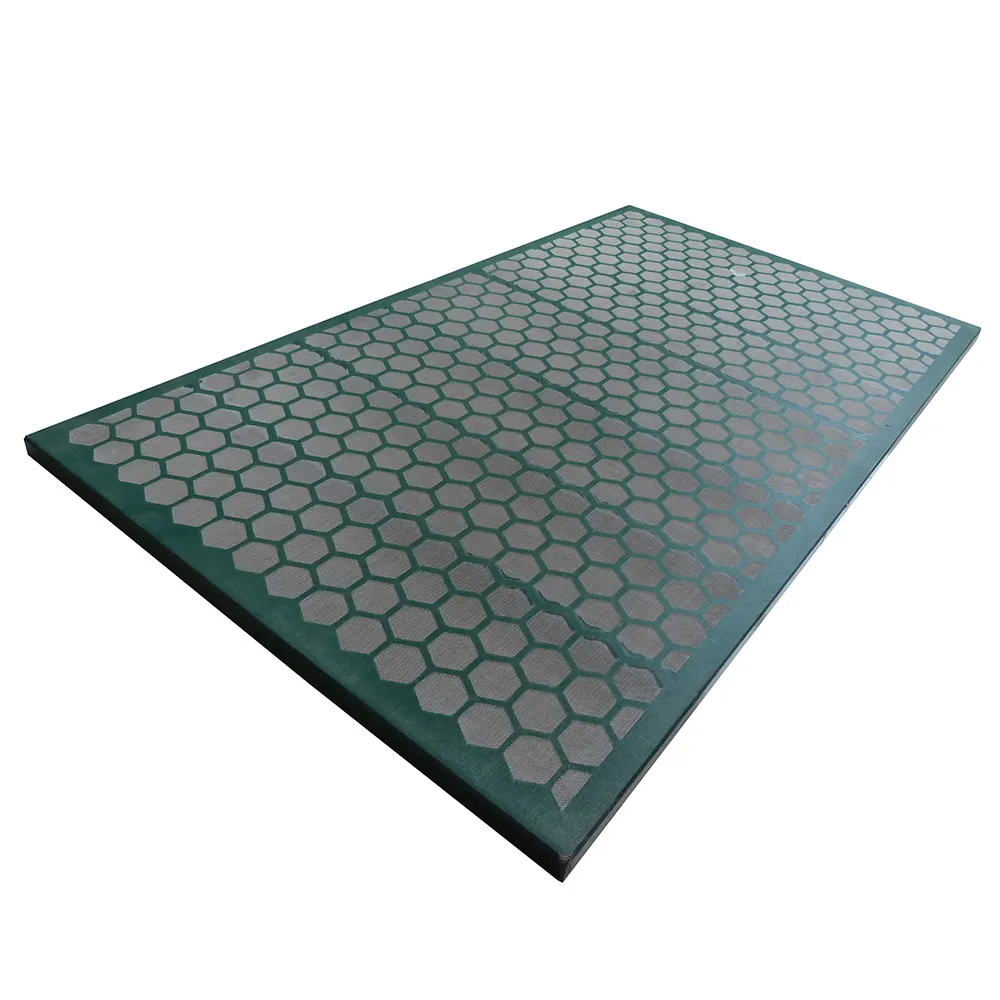

In an industry anchored by reliability and peak operational efficiency, securing accurate derrick shaker screen quotes is more than a procedural step—it is the groundwork for profitability and safety. Shaker screens form the first line of defense during solid-liquid separation, safeguarding downstream equipment and dictating the overall drilling fluid lifecycle costs. Annually, over 25,000 drilling rigs worldwide depend on optimized shaker screen mesh, resulting in an $800M global market as of 2023. Data highlights that selecting the right screen mesh specification can boost drilling fluid recovery efficiency by up to 38%, translating into significant cost reductions and environmental gains. Thus, obtaining precise shale shaker screen mesh quotes is critical for stakeholders demanding a blend of performance, longevity, and competitive pricing.

Technical Advantages: Shaker Screen Design and Mesh Performance

The performance parameters of shaker screens are defined by mesh aperture, wire diameter, layering method, and manufacturing technology. Advanced shaker screen designs now utilize multilayered stainless steel wire cloth (commonly 304 and 316L grades), bolstered by nanotech edge bonding for superior endurance. Analysis demonstrates that screens with optimized mesh grid structures provide:

- 4× longer lifespan compared to traditional single-layer screens

- 20% improved separation accuracy for critical drilling applications

- Enhanced resistance to blinding and delamination, reducing unplanned downtime by 15–30%

Manufacturer Comparison: Price & Performance Metrics

Choosing the optimal shaker screen brand involves balancing upfront investment with lifecycle benefits. Below is a comparative snapshot—based on 2024 data—among the three largest shaker screen suppliers:

| Brand | Standard Mesh Range (API) | Average Lifespan (hours) | Mud Capacity (gpm) | Price/Screen (USD) | Availability of Custom Mesh Quotes |

|---|---|---|---|---|---|

| Derrick Equipment | 20–325 | 350–450 | 500–720 | $75–$120 | Yes |

| Brand Q | 25–270 | 200–350 | 450–650 | $55–$105 | Yes |

| Brand S | 30–300 | 170–320 | 400–610 | $48–$90 | Limited |

Tailor-Made Solutions: Customization Strategies in Shaker Screen Supply

Drilling operations across shale, coalbed methane, geothermal, and offshore hydrocarbon fields demand variable screen architectures. Leading manufacturers are responding by offering custom-fit options based on application-specific feedback. Customization parameters include:

- Mesh count and wire thickness for targeted particle size removal

- Frame material selection—polyurethane, composite, or reinforced steel for chemical and mechanical stress adaptation

- Bespoke branding and packaging for seamless inventory management

- Fast prototype turnaround, with 7–10 day lead times for most mesh variants

Real-World Applications: Success Stories from Field Operations

Case studies from rig operators in Texas’ Permian Basin illustrate the material benefits of data-driven screen selection. In one scenario, a major exploration company adopted high-precision 200 API mesh shaker screens designed for extended service life. Over a six-month campaign drilling 49 wells, this upgrade delivered:

- 38% increase in mud recycling efficiency

- Reduction in screen replacement shutdowns from 21 to 7 events

- Total fluid loss savings calculated at $312,000 USD

How to Select the Right Shaker Screen: Practical Checklist

The ideal shaker screen solution blends technical compatibility with economic rationale. Industry experts recommend the following checklist for buyers requesting shale shaker screen mesh quotes:

- Verify screen compatibility with shaker model (Derrick, Brand Q, Brand S, etc.)

- Define mesh size based on anticipated cuttings profile and mud properties

- Prioritize multi-layered, corrosion-resistant construction for harsh exposure

- Assess available warranties and supply chain agility (local warehousing, expedited delivery)

- Insist on batch-level traceability and independent QA certifications

- Balance upfront cost against expected lifespan (screen price per operational hour)

Conclusion: Optimizing Operations through Accurate derrick shaker screen quotes

Strategic sourcing of derrick shaker screen quotes empowers operators to maximize equipment uptime, minimize fluid losses, and drive down operational expenditures. In an environment where technical specificity, material provenance, and rapid supply chain response are paramount, investing in tailored screening solutions delivers measurable competitive advantages. By rigorously comparing technical features, leveraging custom engineering, and learning from real-world application data, drilling contractors can unlock the full potential of their solids control systems and safeguard project ROI.

(derrick shaker screen quotes)