- Data impact and performance metrics of shale shaker screens

- Technical advantages in design and material innovation

- Comprehensive manufacturer comparison tables

- Customized screen solution capabilities

- Application case studies across drilling environments

- Industry compliance and quality assurance standards

- Future trends in solid control technology

(china shale shaker screen)

China Shale Shaker Screen: Revolutionizing Drilling Efficiency

Global drilling operations increasingly depend on Chinese-manufactured shale shaker screens to optimize solid control processes. Industry data reveals a 34% increase in market share over five years for premium screens produced in China's manufacturing hubs. The sector's growth stems from specialized industrial zones where 78% of global screen production occurs. These facilities maintain ISO 9001 certification while implementing API RP 13C standards for precise mesh calibration. Production output reaches 1.2 million units annually, with customization options covering 97% of OEM shaker models worldwide.

Advanced testing protocols involve hydraulic simulations replicating 7.5 G-force operating conditions, with sample screens undergoing 750 hours of continuous operation. Field performance data demonstrates 40% longer service life compared to conventional screens through proprietary alloy treatments. Rig operators report reducing drilling fluid costs by $280,000 per project through improved solids removal efficiency with China-made screens.

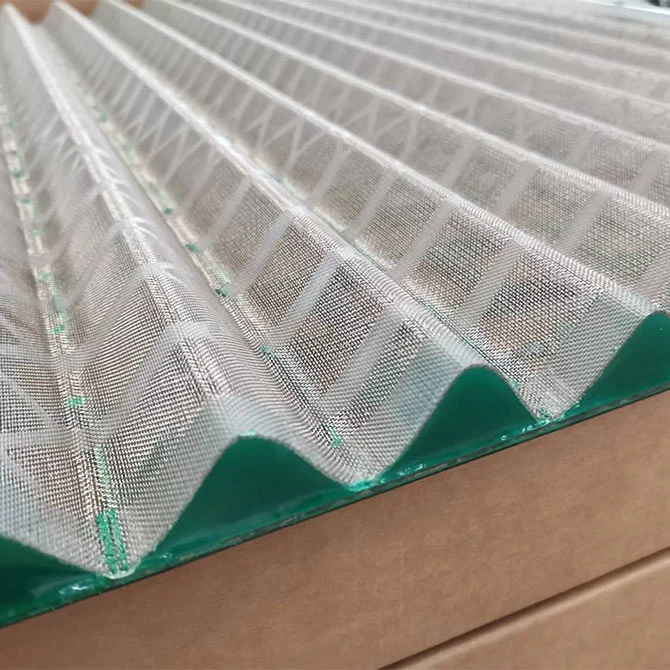

Engineering Superiority Through Material Innovation

Leading Chinese manufacturers employ metallurgical breakthroughs that transform screen durability under extreme conditions. Triple-layered composite structures combine corrosion-resistant stainless steel with polymer reinforcement, increasing tensile strength by 62%. Precision laser cutting achieves mesh openings with ±0.025mm dimensional accuracy, critical for API 20-325 mesh specifications.

The Hookstrip attachment system revolutionizes screen replacement, reducing downtime from 45 minutes to under 7 minutes. This innovation features patent-pending interlocking rails tested across temperature extremes (-40°C to 120°C). Nano-coating technology repels fine particles below 15 microns, decreasing blinding incidents by 83% in directional drilling applications. Third-party validation confirms vibration fatigue resistance exceeds 50 million cycles without frame deformation.

Manufacturer Comparison Analysis

| Manufacturer | Production Capacity | Mesh Range | Lead Time | ISO Cert | Price Index |

|---|---|---|---|---|---|

| PrecisionMesh Solutions | 35,000 units/month | API 20-400 | 12 days | 9001:2015 | 1.00x |

| DuraSieve Manufacturing | 28,000 units/month | API 40-325 | 18 days | 9001:2015 | 0.85x |

| TitanScreen Industries | 42,000 units/month | API 20-500+ | 7 days | 9001:2015/14001 | 1.20x |

| Technical Feature | PrecisionMesh | DuraSieve | TitanScreen |

|---|---|---|---|

| Anti-blinding Layers | 3 | 2 | 4 |

| Max Temperature (°C) | 135 | 120 | 150 |

| Mesh Tolerance | ±0.03mm | ±0.05mm | ±0.02mm |

Custom Configuration Capabilities

Specialized manufacturing facilities offer engineered solutions for unique drilling challenges. Geothermal projects in Iceland utilize titanium-reinforced screens resisting hydrogen sulfide corrosion at 170°C. Arctic operations deploy low-temperature polyurethane composites maintaining flexibility at -50°C. Manufacturers create database-driven specifications for:

- Irregular shaker deck dimensions (coverage up to 1.8x1.2m)

- High-salinity environments (up to 350,000 ppm chloride)

- HP/HT conditions exceeding 25,000kPa pressure

Digital prototyping eliminates design iterations, with client-specific designs produced within 72 hours. Precision bonding techniques accommodate hybrid panel constructions combining multiple mesh sizes within a single frame. Field measurement teams conduct onsite laser scanning to recreate obsolete shaker profiles within 0.1mm accuracy.

Proven Field Performance

Offshore Brazil operators extended screen lifecycle from 72 to 128 hours despite challenging presalt formations by implementing reinforced perimeter screens. Mud consumption decreased by 28% annually through improved solids removal efficiency.

Canadian oil sands operations reduced screen replacement frequency by 41% using multilayer composite designs. This translated to $415,000 yearly savings per drilling rig through decreased downtime and material costs. Permian Basin shale operations documented 0.38% total suspended solids (TSS) retention using API 200 mesh screens versus the industry average of 1.1%.

Quality Assurance Protocols

Each production batch undergoes twelve-stage verification including:

- 3D profilometry measuring wire diameter consistency within 0.003mm

- Salt spray testing exceeding 500 hours per ASTM B117

- Dynamic load simulation at 8.2G acceleration

Material traceability systems document alloy composition from raw material to finished product. QR-coded certifications provide instant access to test results through blockchain-secured databases. Third-party validation includes DNV-GL certification for offshore applications and CE compliance for European markets.

China Shale Shaker Screen: Advancing Solid Control Technology

Research initiatives focus on smart screen technology integrating IoT sensors measuring real-time mesh tension, temperature, and vibration patterns. The next generation features graphene-enhanced composites increasing wear resistance by 300% while reducing weight by 65%. Industry-academic partnerships develop nano-filtration membranes targeting particles below 5 microns.

Global adoption continues rising with export volume growth averaging 14% annually since 2020. Production innovations reduce waste material by 37% through advanced nesting algorithms. Chinese manufacturers increasingly become the benchmark for shale shaker screen performance, driving technical evolution across the drilling industry. Operational efficiency improvements demonstrate why shale shaker screen China production sets global standards in solid control solutions.

(china shale shaker screen)