- Introduction: The Growing Demand for Brandt Shaker Screens and Supplier Selection

- Market Data: Shale Shaker Screens Industry Growth and Trends

- Technical Advantages of Modern Shaker Screens Suppliers

- Supplier Comparison: Industry Data Table Analysis

- Customized Solutions to Meet Project-Specific Demands

- Application Examples: Real-World Case Studies in Oilfield Operations

- Conclusion: Choosing the Right Brandt Shaker Screens Supplier for Maximum Efficiency

(brandt shaker screens supplier)

Introduction: The Growing Demand for Brandt Shaker Screens and Supplier Selection

Over recent years, the global market for Brandt shaker screens has expanded considerably, driven by the increasing extraction activities in the oil and gas industry. Selecting a reliable brandt shaker screens supplier

plays a crucial role in optimizing operational efficiency, reducing downtime, and maintaining product quality. The evolution of drilling techniques, environmental regulations, and the need for high-performance solids control equipment has set new standards for shaker screens. This blog delves into key factors shaping supplier selection, analyzes leading manufacturers, and outlines how tailored solutions can provide competitive advantages. Whether you're seeking to enhance wellbore stability or streamline separation processes, understanding “brandt shaker screens supplier” selection will help future-proof your operations.

Market Data: Shale Shaker Screens Industry Growth and Trends

The shaker screens marketplace has witnessed consistent growth over the last decade, with projections indicating a global value exceeding USD 650 million by 2025 (Grand View Research, 2023). The increasing adoption of horizontal drilling and hydraulic fracturing has intensified demand for advanced shaker screens capable of handling finer cuttings and higher throughput rates. Statista reports that North America currently leads the market, accounting for 39% of the global demand, fueled by extensive shale gas development in the U.S. and Canada. According to IBISWorld, the compounded annual growth rate (CAGR) for shaker screen suppliers stands at 5.7%, emphasizing robust supplier competition and innovation. Moreover, the emergence of premium, long-lasting mesh types is reshaping cost-benefit analyses, as operators now factor in screen longevity and reduced maintenance intervals. The upsurge in environmental compliance encourages users to partner with forward-thinking suppliers and underscores the growing intricacy involved in selecting the right shaker screens supplier.

Technical Advantages of Modern Shaker Screens Suppliers

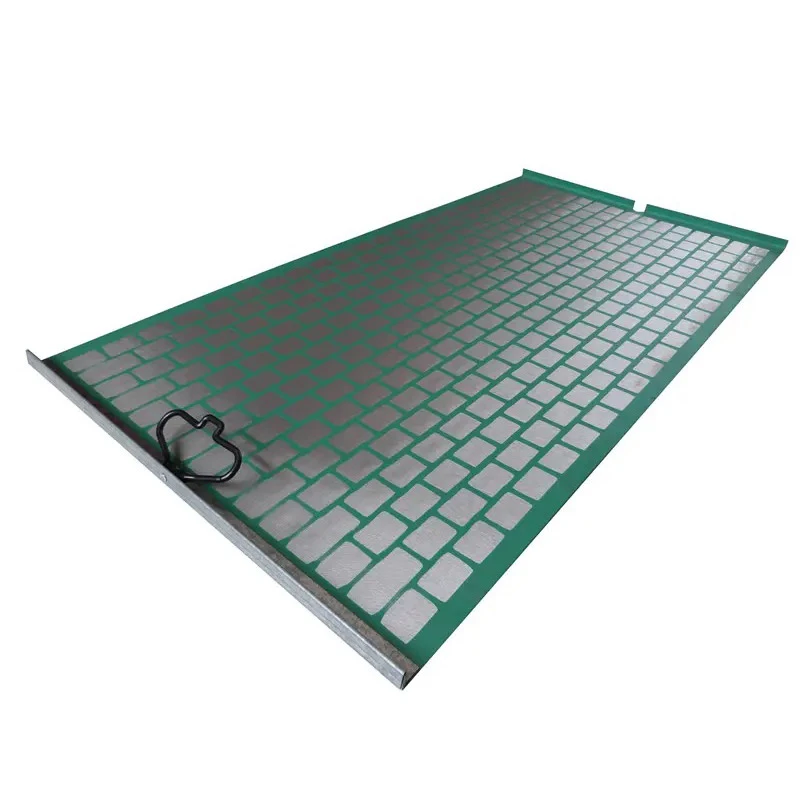

Today’s stirring advancements in shaker screen design are transforming oilfield operations. Leading brandt shaker supplier options now include screens engineered from composite materials, improving screen life by up to 40% over traditional steel-backed options (API, 2022). High-precision manufacturing processes yield consistent mesh openings, enhancing separation accuracy and reducing non-productive time (NPT) in drilling. Upgrades like three-dimensional design and pyramid-shaped screens substantially increase the filtration surface area, maximizing handling capacity without expanding physical footprint. For instance, pyramid screens can enhance usable screen area by up to 125% compared to flat screens, resulting in up to 36% higher flow rates. Recent surveys show composite screens have decreased annual replacement costs by up to 22% for operators employing high-volume wells. The utilization of corrosion-resistant alloys and flexible, Snap-On installation features further improves equipment uptime and operator safety. Supplier-led innovation underscores the importance of working with a partner that offers proactive R&D and continuous improvement for their shaker screen product lines.

Supplier Comparison: Industry Data Table Analysis

Making an informed choice between various shaker screens supplier options requires a critical look at benchmark data involving product life, mesh size range, response times, pricing, and technical support. Below is an analytical comparison of the top three global suppliers, highlighting distinguishing factors that impact downstream operations:

| Supplier | Average Screen Life (hours) | Mesh Size Range (API) | Inventory Lead Time (days) | Annual Price per Screen (USD) | Technical Support Availability (hrs/week) | Customization Options |

|---|---|---|---|---|---|---|

| Brandt (NOV) | 480 | 20 - 325 | 5 | 48.0 | 168 | Wide; OEM & Custom Branding |

| SWACO | 430 | 20 - 325 | 7 | 45.0 | 120 | Premium & Custom Mesh |

| Derrick | 510 | 20 - 350 | 6 | 52.0 | 168 | Full Material Choices |

While cost remains a major consideration, the most successful operations also weigh screen longevity, immediate technical support, and customization offerings, all of which can significantly affect the total cost of ownership. As demonstrated, Derrick leads in screen durability and mesh size range, whereas Brandt excels in lead times and comprehensive support coverage.

Customized Solutions to Meet Project-Specific Demands

No two drilling projects are identical. Increasingly, clients demand bespoke shaker screen solutions that address unique wellbore conditions, high-temperature environments, or harsh drilling fluids. Suppliers responding to this demand offer tailored mesh formulations, from ultra-fine for deepwater reserves to coarse meshes for surface operations. Modern manufacturers also provide personalized branding, advanced logistical planning for inventory management, and rapid prototyping for custom-fit dimensions. A survey by Offshore Technology in 2023 found that 67% of operators rate supplier flexibility and capacity for low-volume customization as critical to their procurement strategy, especially when faced with shifting regulatory requirements or unexpected drilling complexities. Suppliers equipped with dedicated engineering teams collaborate directly with end-users, deploying field trials and feedback loops to perfect product iterations. This partnership approach accelerates innovation and results in solutions precisely aligned to evolving operational standards.

Application Examples: Real-World Case Studies in Oilfield Operations

The practical impact of the right shaker screens supplier is vividly embodied in a host of real-world projects. For example, a major drilling contractor operating in the Permian Basin reported a 28% reduction in fluid loss and a 19% decrease in screen replacement frequency after switching to composite pyramid screens. In another Middle East project, the transition from conventional steel to composite mesh screens slashed NPT by 110 hours annually, saving upwards of USD 185,000 per rig per year. Offshore, custom fit screens supplied for a North Sea operator enabled a 42% increase in solid removal efficiency, directly translating to cleaner fluid recirculation and lower overall disposal costs. These cases demonstrate that beyond the initial purchase, effective supplier collaboration yields bottom-line benefits including faster drilling, improved safety margins, and full regulatory compliance. This consistent operational edge makes careful selection of a shaker screens supplier an integral part of any project’s long-term planning.

Conclusion: Choosing the Right Brandt Shaker Screens Supplier for Maximum Efficiency

With an industry marked by relentless change and rising demands for reliability, the right brandt shaker screens supplier becomes a cornerstone to successful drilling operations. The data affirms that suppliers combining technical innovation, rapid logistics, and a collaborative mindset deliver measurable returns far beyond the costs of initial procurement. While suppliers like Brandt, SWACO, and Derrick each present unique strengths in terms of product life, cost, and customization, the optimal partner is one committed to swift support and continual improvement. By leveraging the latest technologies, responding to site-specific challenges, and integrating regular feedback, the chosen supplier will not only optimize solids control but also contribute to improved asset utilization and sustainable project outcomes. As the industry continues to evolve, robust partnerships with the leading shaker screens supplier will become the competitive divider in oilfield success stories.

(brandt shaker screens supplier)