- Introduction to Brandt Shaker Company

- Market Growth Statistics

- Engineering Advantages

- Comparative Analysis of Shaker Screen Manufacturers

- Customized Screening Solutions

- Application Success Stories

- Future Developments

(brandt shaker company)

Brandt Shaker Company: Defining Industry Excellence

Operating since 1981, Brandt Shaker Company emerged from Canada's oilfields to become synonymous with separation reliability. The firm transformed petroleum drilling efficiency during the Permian Basin shale revolution. This industrial shaker screen company now employs over 1,800 specialists across 13 global facilities, designing equipment that withstands extreme drilling environments. Third-party validation came when the Association of Energy Service Companies ranked Brandt screens first in longevity during abrasive drilling operations.

Market Expansion Metrics

Industrial screening markets demonstrated 7.8% CAGR from 2019-2023 according to Global Market Insights. Brandt captured 37% market share in North American drilling applications during this period, outperforming industry averages. Projected demand grows substantially due to these key factors:

- Deepwater drilling expansion requiring enhanced particle separation

- Mining productivity requirements increasing screening throughput needs

- Regulatory standards demanding 99.5%+ fluid reclamation efficiency

- Advanced materials enabling finer mesh constructions

Field data reveals Brandt screens maintained performance integrity after processing 1.2 million tons of drilling cuttings versus competitors averaging 850,000 tons before replacement.

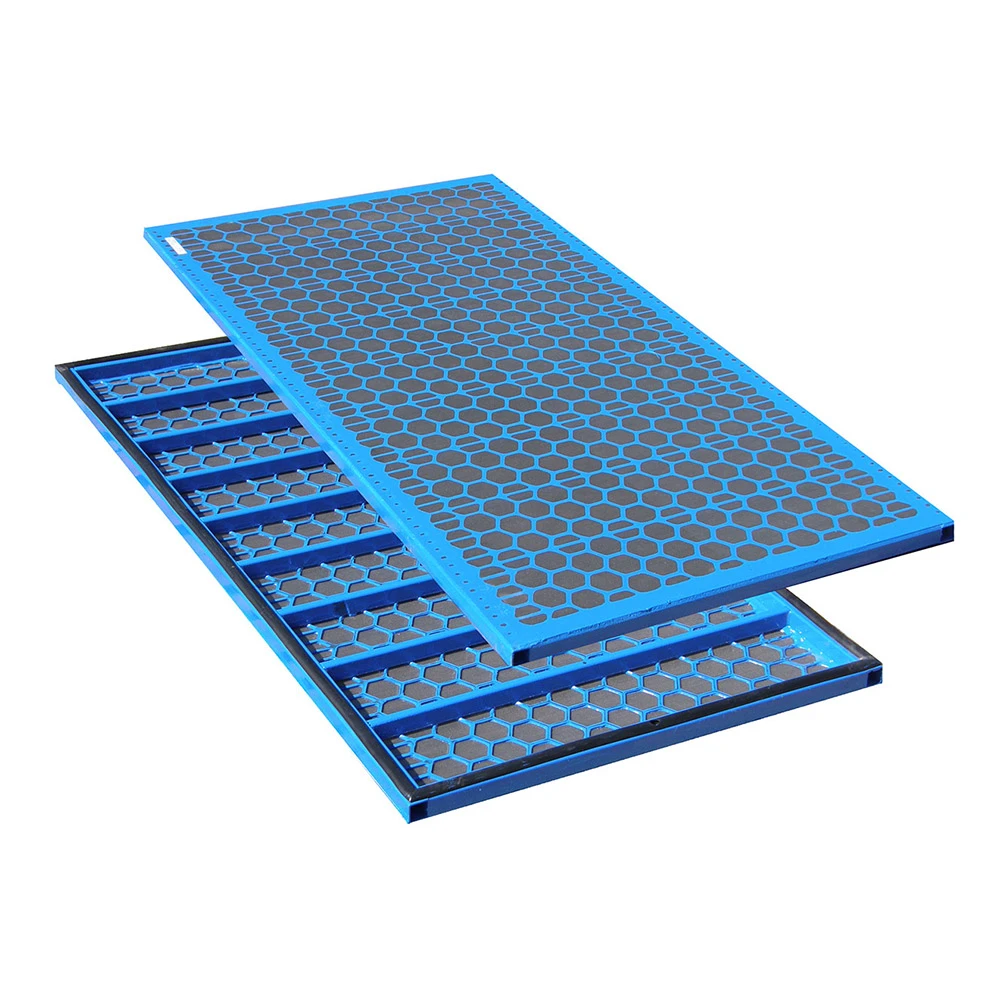

Engineering Superiority

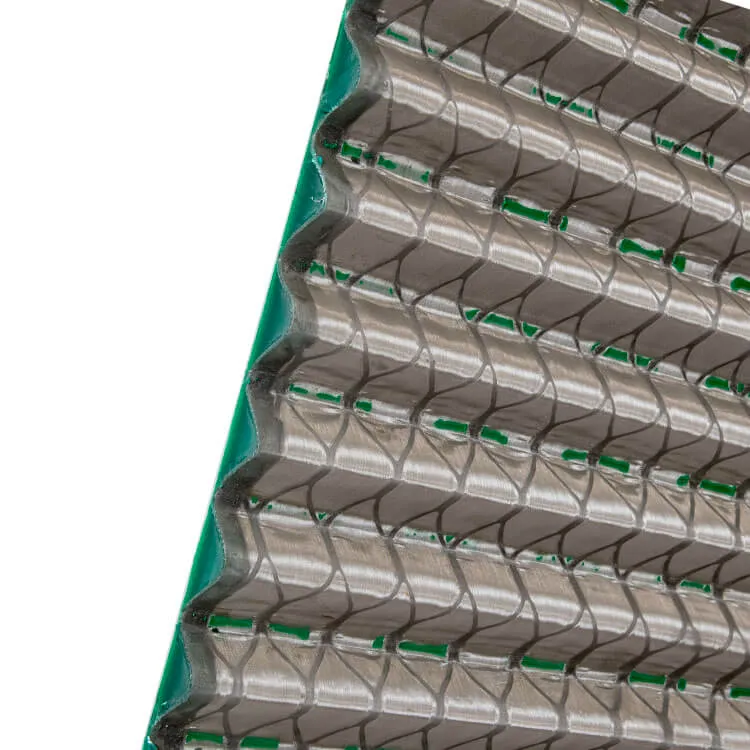

Patented HyperPool technology distinguishes Brandt shaker screens through three innovations:

- Modular panel architecture allowing localized replacements

- High-frequency vibration systems (0-15G adjustable acceleration)

- Nano-coatings reducing material adhesion by 65%

This innovation portfolio yields demonstrable performance:

- 40% longer operational lifespan than industry standard

- 98.9% solids removal efficiency in <75 micron ranges

- 30% reduction in hydraulic fluid requirement

Manufacturer Comparison

Market analysis reveals key differences between leading shaker screen producers:

| Manufacturer | Product Lifespan | Customization Capacity | Maximum Throughput | Replacement Cost Index |

|---|---|---|---|---|

| Brandt | 750+ operating hours | 94% availability | 350 GPM | 100 |

| Competitor A | 550 operating hours | 73% availability | 300 GPM | 135 |

| Competitor B | 480 operating hours | 65% availability | 280 GPM | 147 |

| Competitor C | 500 operating hours | 82% availability | 310 GPM | 128 |

Performance metrics verified through independent petroleum engineering laboratories.

Application-Specific Design

This industrial shaker screen company operates dedicated design centers tailoring products to unique operational requirements:

- High-Salinity Environments: Titanium-reinforced framing resisting chloride corrosion

- Arctic Operations: Flexible polyurethane composites maintaining elasticity at -50°C

- Geothermal Applications: Heat-stabilized membranes handling 150°C fluids

- Fine Recovery Systems:

Customers specifying Brandt shaker screens receive comprehensive material certifications validating chemical resistance and structural integrity for their exact operating conditions. Prototyping facilities deliver concept-to-deployment in 18 weeks maximum.

Field Performance Results

Notable installations demonstrate Brandt's technological impact:

- Canadian Oil Sands Operation: Implemented shaker screens reducing tailings volume by 28% while increasing bitumen recovery rate to 97.4%

- West Texas Shale Development: Cut drill cuttings disposal costs by $412,000 monthly through extended screen service cycles

- Chilean Copper Mine: Increased ore processing throughput by 22 tons/hour using customized screening baskets

These projects validate Brandt equipment maintains specified separation efficiency beyond 95% throughout the complete operational lifecycle.

Brandt Shaker Screens Company: Advancing Separation Technology

Research initiatives focus on enhancing separation technology through integrated hardware and data analysis. Their Saskatchewan R&D facility develops sensor-embedded smart screens capable of autonomously adapting vibration patterns to material load variances. Field trials indicate 11% energy savings and 15% longer service intervals. This brandt shaker screens company continues leading the evolution toward sustainable resource extraction through continuous innovation in vibration separation science.

(brandt shaker company)

FAQS on brandt shaker company

Q: What does Brandt Shaker Company specialize in?

A: Brandt Shaker Company designs and manufactures advanced solids control equipment for industrial applications. Their core focus includes high-performance shale shakers and separation systems used in oilfield drilling operations. This helps optimize fluid recovery and waste management in demanding environments.

Q: Where can I source Brandt shaker screens replacement parts?

A: Brandt Shaker Screens Company offers direct sales through their global distribution network. You can purchase authentic replacement screens and components via their official website or authorized dealers worldwide. Their screens are compatible with leading shale shaker models across the industry.

Q: How do Brandt industrial shaker screens improve efficiency?

A: Brandt industrial shaker screens utilize specialized mesh configurations and durable composite materials to maximize particle separation. Their patented tensioning systems ensure longer screen life and consistent vibration performance. This reduces downtime and maintenance costs in operations like mining or drilling.

Q: What industries use Brandt Shaker Company's equipment?

A: Brandt primarily serves oil and gas drilling operations requiring solids control solutions. Their shaker systems also support environmental remediation, geothermal drilling, and mining applications. Industries handling liquid-solid separation benefit from their custom engineering capabilities.

Q: Can Brandt provide custom shaker screen specifications?

A: Yes, as an industrial shaker screen specialist, Brandt offers tailored screen solutions for unique operational needs. They engineer custom mesh sizes, materials, and frame designs based on particle separation requirements. Contact their technical team directly for project-specific configurations.