In environmental wastewater treatment, shale shaker screens are increasingly being applied as an effective method for primary solids separation in both industrial and municipal settings. Originally designed for the oil and gas industry, these vibrating screens have proven to be versatile tools in removing suspended solids from wastewater streams, especially in situations where conventional filtration or sedimentation systems may be inefficient or impractical. Shale shaker screens operate by using vibratory motion to move slurry or wastewater across a screen mesh, allowing water and fine particles to pass through while larger solids are retained and discharged.

This method is highly effective in pre-treatment stages, where removing coarse particles early can significantly reduce the load on downstream biological or chemical treatment systems. In industries such as food processing, pulp and paper, construction, mining, and chemical manufacturing, wastewater often contains fibrous, abrasive, or granular solids that can clog pipes, damage pumps, or interfere with treatment efficiency. By installing shale shaker screens at the front end of treatment plants, operators can capture these solids, reduce maintenance requirements, and improve the overall system performance. In municipal wastewater facilities, shale shaker screens can be used as part of stormwater treatment or combined sewer overflow (CSO) systems to intercept debris, plastic waste, and sediment before the water enters biological tanks or lagoons.

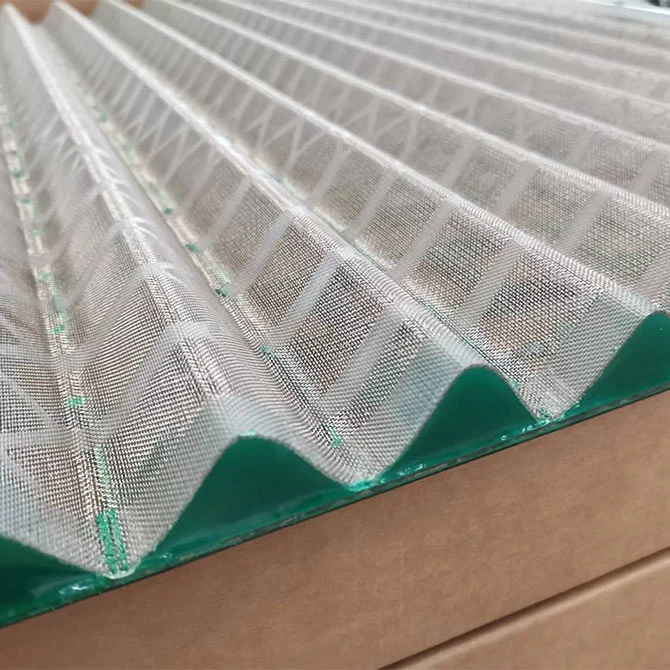

The use of shaker screens also supports water reuse initiatives by improving the clarity and quality of recycled water. Shale shaker screens come in various mesh sizes and configurations, including single-layer and multi-layer designs, to suit different particle sizes and flow rates. Materials such as stainless steel and polymer-coated mesh are commonly used for corrosion resistance and durability in harsh wastewater environments. Some systems are designed with automated cleaning mechanisms or adjustable vibration settings to prevent screen blinding and maintain consistent throughput. The benefits of using shale shaker screens in wastewater treatment include higher separation efficiency, reduced chemical usage, lower sludge volumes, and improved plant reliability.

They also offer a relatively compact and energy-efficient alternative to large settling tanks or complex filtration systems. In the context of environmental sustainability, shale shaker screens contribute to reduced water consumption, minimized environmental discharge, and compliance with increasingly strict regulatory standards. With growing pressure on industries and municipalities to treat water more effectively and economically, the application of shale shaker screens offers a practical solution for enhancing primary treatment and protecting downstream infrastructure. As wastewater treatment technologies evolve, shale shaker screens continue to gain recognition as a reliable and flexible component in modern solids management systems. Their simple design, adaptability, and robust construction make them well-suited for integration into new treatment facilities as well as retrofitting existing plants seeking to improve performance and reduce operational costs.