In mining and tunneling engineering, shale shaker screens are increasingly used as a key component in solids separation and slurry treatment systems. These operations often generate large volumes of slurry—a mixture of water, soil, rock particles, and sometimes drilling additives—during excavation, drilling, or blasting. Whether in hard rock mining, coal extraction, or underground tunneling for subways, highways, or hydroelectric projects, effective separation of solids from slurry is essential for environmental management, equipment protection, and material recycling. Shale shaker screens, originally developed for oil and gas drilling, have proven highly effective in these scenarios due to their ability to handle high flow rates, separate fine particles, and operate continuously in demanding environments.

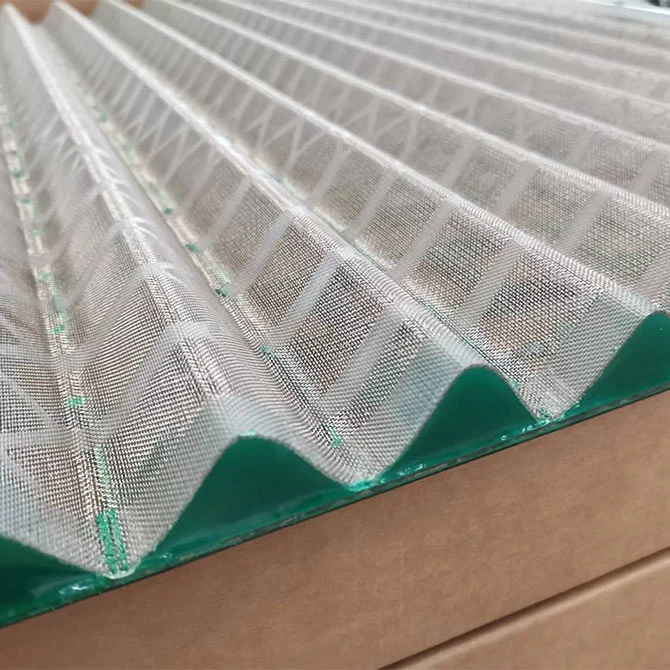

In tunneling, for instance, tunnel boring machines (TBMs) produce significant amounts of spoil mixed with water. This spoil must be processed to remove coarse and fine solids before the water can be reused or safely discharged. Shale shaker screens mounted on vibrating shakers are used as the first stage of treatment to remove large debris and fine cuttings from the slurry. This prevents blockages in pumps, pipelines, and downstream filtration equipment. Similarly, in mining operations, where dewatering of tailings or separation of valuable minerals from waste rock is required, shaker screens offer an efficient, low-maintenance solution for primary solid-liquid separation. The screens are typically constructed with stainless steel or polyurethane mesh, offering high wear resistance and chemical durability, particularly in abrasive or acidic mining environments. Multi-layer designs and various mesh sizes (e.g., API 40 to API 200 equivalents) are used depending on the type and size of particles to be separated. Some advanced systems also feature adjustable vibration patterns to optimize separation for different materials.

The benefits of using shale shaker screens in these industries are numerous: they reduce water usage by enabling closed-loop slurry systems, lower disposal volumes and costs, and help meet increasingly strict environmental regulations regarding effluent quality and waste management. Moreover, cleaner process water results in longer equipment life, reduced maintenance needs, and more consistent excavation or processing performance. In large-scale tunneling projects, such as metro systems in urban areas or underground hydropower stations, compact solids control systems with shaker screens are preferred due to limited space and the need for fast, continuous operation. Mining companies also use shaker screens in portable or fixed installations near drilling or excavation sites to improve operational efficiency and reduce transportation of slurry. Overall, shale shaker screens provide a reliable, cost-effective, and environmentally friendly solution for managing solids in mining and tunneling projects. Their versatility, high separation efficiency, and durability make them a valuable asset in supporting safe, clean, and efficient underground construction and resource extraction.