In geothermal energy development, shale shaker screens play a vital role in maintaining the efficiency and reliability of drilling operations, particularly during the early stages of well construction. Similar to oil and gas drilling, geothermal wells require the circulation of drilling fluid to transport cuttings from the wellbore to the surface, cool the drill bit, and maintain formation stability. As the drilling fluid returns to the surface, it carries rock cuttings, sand, and other solid debris that must be removed before the fluid can be reused. This is where shale shaker screens come into play. Mounted on vibrating shale shakers, these screens filter out solids from the fluid, allowing for its recirculation and reducing the volume of waste. Geothermal environments often present unique challenges for solids control due to high temperatures, abrasive rock formations, and variable drilling conditions.

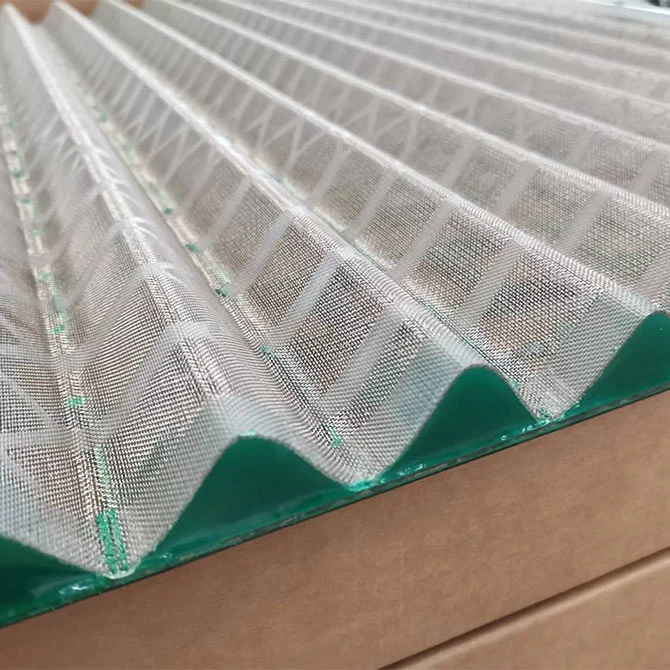

The solids encountered in geothermal wells—typically volcanic rock fragments, silica-rich particles, and heavy mineral debris—can be particularly harsh on equipment. Therefore, shale shaker screens used in geothermal drilling must be constructed with high-strength, heat-resistant materials that can withstand prolonged exposure to elevated temperatures and corrosive fluids. Multi-layer composite screens, stainless steel mesh, and reinforced frames are commonly used to ensure durability and performance. Efficient screening of solids helps to preserve the rheological properties of the drilling fluid, reducing wear on downstream equipment such as mud pumps and centrifuges, and minimizing the risk of lost circulation or wellbore instability. In geothermal projects, where the cost of drilling is significant and well depths can exceed several kilometers, maintaining clean and stable drilling fluid through effective solids control is critical to project success. Moreover, as environmental regulations in geothermal development become more stringent, proper management of drilling waste and fluid recycling becomes a key concern. Shale shaker screens contribute to environmental compliance by reducing the need for fresh water, lowering disposal volumes, and supporting sustainable drilling practices.

In regions with active geothermal development, such as Iceland, Kenya, Indonesia, and parts of the United States, the implementation of advanced shale shaker screen technologies has helped improve drilling performance and reduce operational costs. The use of fine mesh screens, wave-type screen designs, and automated shaker systems has further enhanced solids separation efficiency, even in the most demanding geothermal fields. Overall, shale shaker screens serve as an essential component of the solids control system in geothermal drilling, ensuring fluid integrity, protecting equipment, and supporting the long-term viability of geothermal energy as a clean and renewable resource.